The Game-Changer in Water Bottle Manufacturing

Have you ever wondered how those BIG water bottles that sit on top of office water coolers are made? The answer lies in amazing machines called semi-automatic PET blow molding machines. These incredible devices are changing the way companies make 5-gallon (20-liter) water bottles around the world.

Think about it – every day, millions of people drink water from these large bottles. From offices to homes, from schools to hospitals, these containers are everywhere. But making them isn’t as simple as you might think. It requires special technology & precise engineering to create bottles that are strong, safe, and reliable.

The semi-automatic PET blow molding machine is like a magical factory worker that never gets tired. It takes small plastic pieces called preforms & transforms them into full-sized water bottles through a process that involves heat, air pressure, & careful timing. This technology has made it possible for businesses of all sizes to enter the water bottle manufacturing industry without spending millions of dollars on equipment.

What makes these machines so SPECIAL is their perfect balance between automation & human control. Unlike fully automatic machines that cost a fortune, semi-automatic versions allow operators to have more control while still enjoying the benefits of modern technology. This means smaller companies can compete with bigger manufacturers & create high-quality products at reasonable prices.

Understanding PET Material: The Building Block of Modern Water Bottles

PET stands for Polyethylene Terephthalate, which sounds complicated but is actually a very common type of plastic. You probably use PET products every single day without even knowing it! This material is perfect for making water bottles because it’s lightweight, strong, & completely safe for storing drinking water.

Why do manufacturers choose PET over other materials? First, PET is crystal clear, which means customers can see the water inside the bottle. This transparency builds trust because people want to know their water looks clean & fresh. Second, PET doesn’t break easily like glass, making it much safer to handle & transport. Imagine trying to deliver heavy glass water bottles to offices – it would be a nightmare!

The recycling benefits of PET are AMAZING too. These bottles can be melted down & turned into new products, including new bottles, clothing, carpets, & even stuffing for pillows. This helps protect our environment by reducing waste. Many companies now advertise that their bottles are made from recycled PET, which makes environmentally conscious customers happy.

PET material also resists chemicals & doesn’t absorb flavors or odors. This means your water will taste exactly like water, not like plastic. The material can handle temperature changes without cracking or becoming brittle. Whether the bottle sits in a hot delivery truck or a cold storage room, it maintains its strength & shape. These properties make PET the top choice for water bottle manufacturers worldwide.

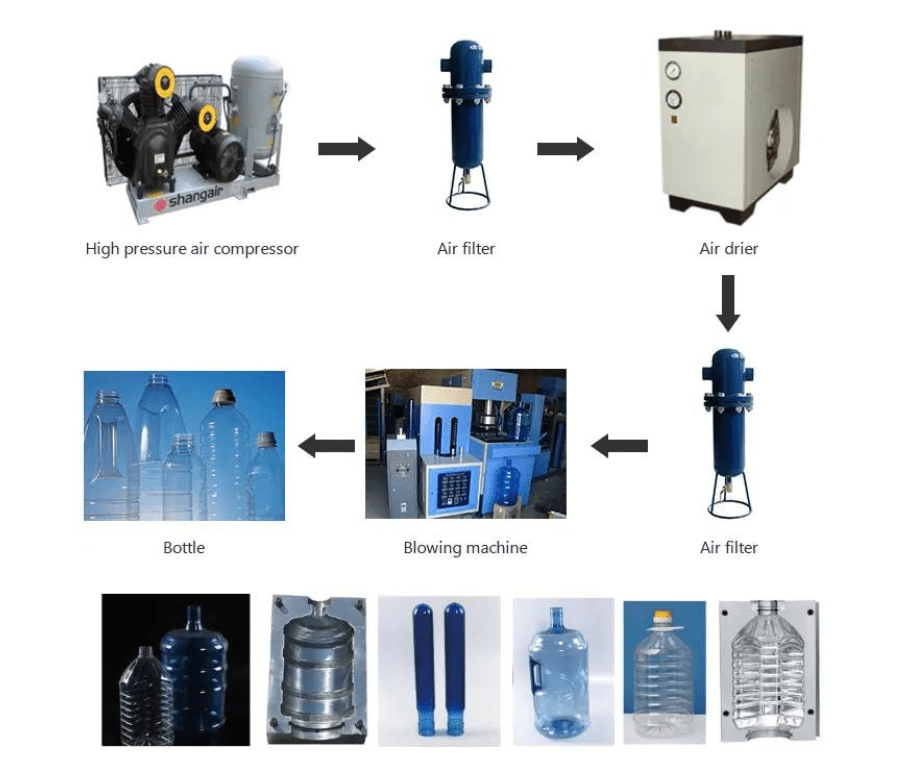

How Semi-Automatic Blow Molding Machines Work: The Magic Behind the Process

The blow molding process is like watching magic happen right before your eyes. It starts with small plastic tubes called preforms that look nothing like the final bottles. These preforms are made in a separate process & then shipped to bottle manufacturers. Think of them as the “seeds” that will grow into full-sized bottles.

First, the machine heats up the preforms to exactly the right temperature. This heating process is CRUCIAL because if the preforms get too hot, they’ll melt completely. If they don’t get hot enough, they won’t stretch properly. The heating happens in a special oven section of the machine where infrared heaters warm the preforms evenly from all sides.

Next comes the exciting part – the actual blowing! The heated preform gets placed into a metal mold that’s shaped exactly like the final bottle. Then, high-pressure air gets blown into the preform, causing it to expand & press against the walls of the mold. It’s similar to blowing up a balloon, except the balloon is made of hot plastic & gets pressed into a specific shape.

The cooling process happens quickly after the bottle takes its final shape. Cold water or air helps the plastic harden in its new form. Once cooled, the mold opens up & reveals a perfect 5-gallon water bottle! The entire process from preform to finished bottle takes only a few minutes. Operators can watch each step & make adjustments as needed, which is why these machines are called “semi-automatic.”

Key Features & Benefits of Semi-Automatic Systems

Semi-automatic machines offer the perfect balance between cost & efficiency for many businesses. Unlike fully manual processes that require lots of workers, or fully automatic systems that cost hundreds of thousands of dollars, semi-automatic machines provide an affordable middle ground. Small & medium-sized companies can start their water bottle production without taking huge financial risks.

The FLEXIBILITY of these machines is incredible. Operators can easily change bottle designs by switching molds. Want to make bottles with different shapes or handle designs? No problem! This adaptability allows manufacturers to serve various customers with different preferences. Some clients might want bottles with built-in handles, while others prefer simple designs. The same machine can produce both types.

Quality control becomes much easier with semi-automatic systems. Since operators are involved in each step, they can spot problems immediately & make corrections. If a bottle doesn’t look right, they can adjust the temperature, pressure, or timing right away. This hands-on approach often results in fewer defective products compared to fully automatic systems that might produce hundreds of bad bottles before anyone notices a problem.

Energy efficiency is another major advantage. These machines use less electricity than fully automatic systems because they don’t have as many motors, sensors, & computer systems running constantly. Lower energy consumption means lower operating costs, which helps businesses stay profitable. The maintenance requirements are also simpler, meaning companies don’t need to hire expensive technicians for regular upkeep.

Training operators to use semi-automatic machines is relatively straightforward. Most people can learn the basics in a few days & become experts within weeks. This accessibility means companies can find qualified workers more easily & don’t have to pay extremely high wages for specialized technicians.

Market Applications & Business Opportunities

The demand for large water bottles continues growing every year as more people become health-conscious & businesses provide clean drinking water for employees. This growing market creates excellent opportunities for entrepreneurs & existing manufacturers to expand their businesses. Office buildings, schools, hospitals, & homes all need reliable supplies of bottled water.

Starting a water bottle manufacturing business with semi-automatic equipment requires much less capital than most people think. While the initial investment might seem significant, the return on investment can be quite fast if you have steady customers. Many successful businesses started with just one machine & gradually expanded as their customer base grew.

The VERSATILITY of these machines opens doors to various market segments. Besides plain water bottles, manufacturers can produce bottles for flavored water, sports drinks, & even some cleaning products. Different industries have different requirements for bottle thickness, shape, & size, but the same basic equipment can handle these variations with minor adjustments.

Export opportunities are also exciting for bottle manufacturers. Many developing countries need reliable sources of quality water bottles but don’t have local manufacturing capabilities. Companies that invest in semi-automatic blow molding machines can potentially supply bottles to international markets, significantly increasing their revenue potential.

Small-scale manufacturers often find success by focusing on local markets first. Building relationships with nearby offices, schools, & water delivery services can provide steady income while the business establishes its reputation. As quality & reliability become known in the local market, expansion to regional & national customers becomes possible.

Conclusion: Your Gateway to Success in Water Bottle Manufacturing

Semi-automatic PET 5-gallon 20-liter water bottle making blow molding machines represent an incredible opportunity for businesses ready to enter or expand in the beverage container industry. These machines combine affordability, reliability, & quality in ways that make sense for companies of all sizes. Whether you’re an entrepreneur looking for your first business venture or an established manufacturer considering diversification, these machines deserve serious consideration.

The technology behind blow molding continues improving every year, making machines more efficient, easier to operate, & more environmentally friendly. Companies that invest in this equipment today position themselves to benefit from growing demand for bottled water & the ongoing shift toward sustainable packaging solutions.

Success in this industry requires more than just buying equipment. You’ll need to understand your local market, build relationships with suppliers & customers, & maintain high quality standards. However, the fundamentals are straightforward, & the potential rewards make the effort worthwhile.

Are you ready to explore the possibilities? Research local suppliers, visit manufacturing facilities if possible, & talk to current machine operators about their experiences. The water bottle industry needs innovative companies that can deliver quality products reliably & affordably. With the right equipment & dedication, your business could become the next success story in this growing industry.

The future of water bottle manufacturing is bright, & semi-automatic blow molding machines are leading the way. Don’t let this opportunity pass by – start planning your entry into this exciting field today!

Ready to boost your large bottle manufacturing with semi-automatic PET blow molding technology? Contact us today to discover the ideal machine for your production requirements.